Introduction

Have you ever looked at a price tag at the grocery store or browsed online stores and observed a seemingly random stream of letters and numbers? These codes, which are sometimes referred to as SKU numbers, are a crucial component of the background that ensures a seamless purchasing experience. However, what are SKUs precisely, and how are they used by businesses? This article delves into the world of SKU numbers, describing their purposes and the various applications that allow businesses to effectively manage their inventory.

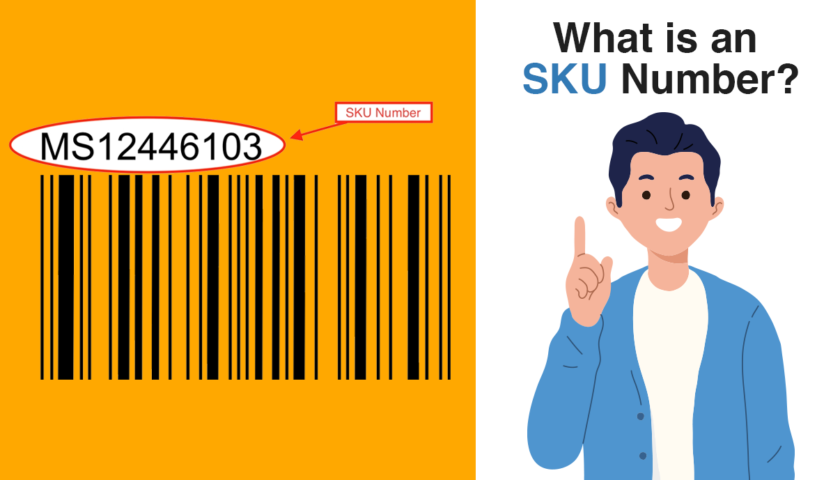

What is an SKU Number?

An SKU number, which stands for Stock Keeping Unit, is a unique identifier assigned to a specific product by a business. Think of it as a product’s fingerprint in the vast world of inventory. These codes, typically alphanumeric (containing both letters and numbers), can vary in length depending on the business’s needs but usually range from 6 to 12 characters.

How Businesses Use SKU Numbers

SKU numbers offer a multitude of benefits for businesses, streamlining various aspects of inventory management:

1. Inventory Management:

Imagine a large warehouse filled with countless products. With a quick scan of the SKU code, businesses can determine the exact quantity of a particular product in stock, preventing stockouts (running out of a product) and ensuring they always have enough inventory to meet customer demands. SKUs also help with precise reordering, ensuring that stores are kept stocked and business operations go without a hitch.

2. Product Identification:

SKU numbers go beyond simply identifying a product. Additionally, they can encode variants inside a product category. For instance, a business selling T-shirts might have a single SKU for all small-sized T-shirts. However, within that SKU, variations like color (red, blue, etc.) can be further distinguished using additional characters in the code. In warehouses and fulfillment centers, the picking and packing procedure is made easier by this thorough product identification. When an order comes in for a specific color and size of a T-shirt, the SKU code pinpoints the exact item, minimizing errors and ensuring correct product fulfillment.

3. Sales Analysis:

SKUs can be connected to sales information in addition to tracking inventory. They can identify which products are selling well, which ones might be less popular, and even spot seasonal variations in demand.

How to Create SKU Numbers

There isn’t a single, universal method for determining SKU numbers. However, some general strategies can enhance the effectiveness of your SKU system:

- Include Relevant Details: Consider incorporating essential product information into the SKU code. This might include details like brand, size, color, or material. This degree of specificity makes it simpler to identify products and optimizes warehouse processes.

- Maintain Consistency: Consistency is key! Your SKU system should have a well-defined and consistent structure that is applied consistently to all of your products. Everyone in your company, from salespeople to warehouse workers, can effectively comprehend and interpret SKU codes because of this consistency.

SKU Management: Keeping Track of Your Stock

SKU management refers to the ongoing process of maintaining accurate and up-to-date information associated with each SKU code. This incorporates consistently checking stock levels, guaranteeing product details encoded inside the SKU stay exact, and mirroring any progressions in item varieties or estimating. Powerful SKU management is basic for keeping a strong and facilitated stock, preventing stock mistakes, and ensuring smooth business errands.

SKUs and Barcodes

You might have noticed barcode labels alongside SKU codes on many products. These barcodes essentially represent a machine-readable version of the SKU code. The data encoded within the barcode lines corresponds to the unique SKU number assigned to the product. This data may be swiftly and accurately read by barcode scanners, greatly simplifying inventory management procedures.

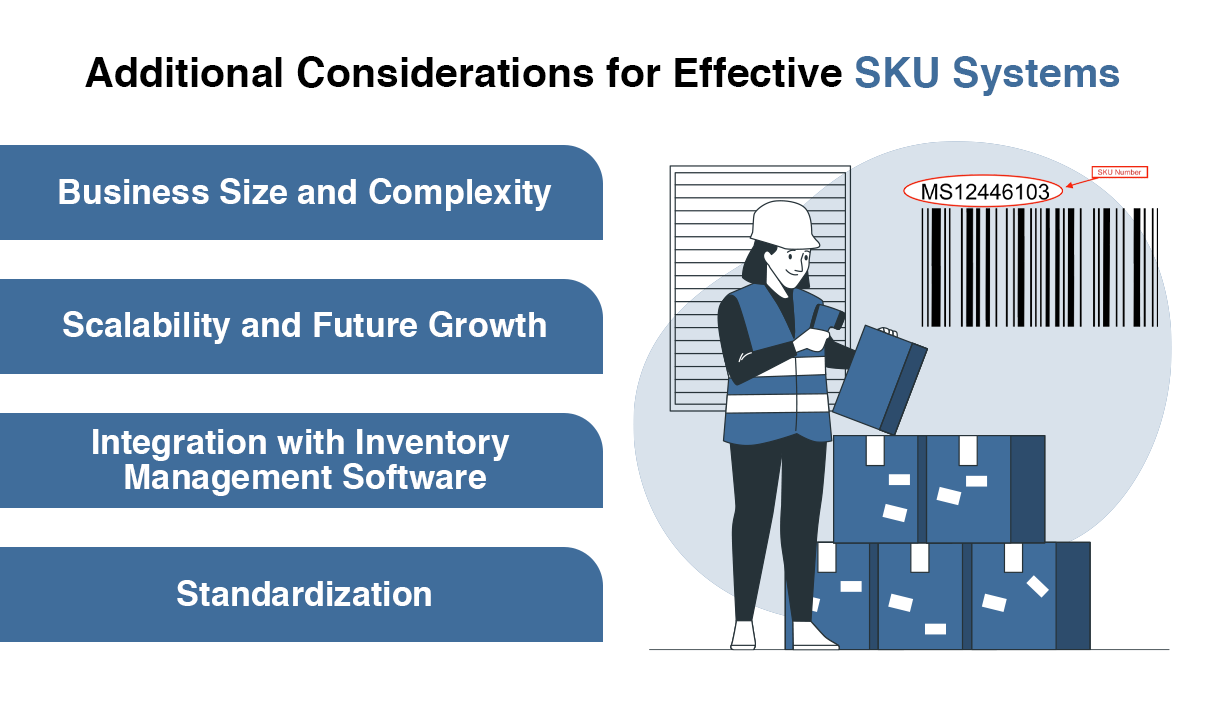

Additional Considerations for Effective SKU Systems

While creating a basic SKU system is a good starting point, there are additional factors to consider for a truly effective and scalable solution:

- Business Size and Complexity: The complexity of your SKU system should align with the size and nature of your business. A small store with a limited product range might require a simpler system compared to a large online retailer with thousands of variations across diverse product categories.

- Scalability and Future Growth: As your business grows and your product range expands, your SKU system should be adaptable. Consider incorporating flexibility into your system to accommodate future additions and variations without needing a complete overhaul.

- Integration with Inventory Management Software: Many businesses utilize inventory management software to streamline stock tracking, order processing, and other crucial tasks. Ensure your SKU system integrates seamlessly with your chosen software for optimal efficiency and data accuracy.

- Standardization: If you operate across multiple locations or collaborate with suppliers or distributors, consider adopting standardized SKU practices. This facilitates smoother communication, simplifies data exchange, and minimizes potential confusion.

Best Practices for SKU Management

Effective SKU management goes beyond simply creating the codes. Here are some best practices to ensure your SKU system functions optimally:

- Regular Audits and Reviews: Conduct periodic audits of your inventory to verify physical stock levels against the data linked to your SKUs. This helps identify discrepancies and ensures your SKU system reflects accurate information.

- Clear Documentation: Maintain clear and up-to-date documentation for your SKU system. This documentation should explain the logic behind your chosen format, the meaning of specific characters within the code, and any product variations associated with each SKU.

- Employee Training: Train your staff on understanding and utilizing your SKU system. This empowers them to effectively locate products, process orders accurately, and contribute to maintaining a well-organized inventory.

- Continuous Improvement: As your business evolves, your SKU system might require adjustments. Be open to refining your system based on practical experience and evolving needs.

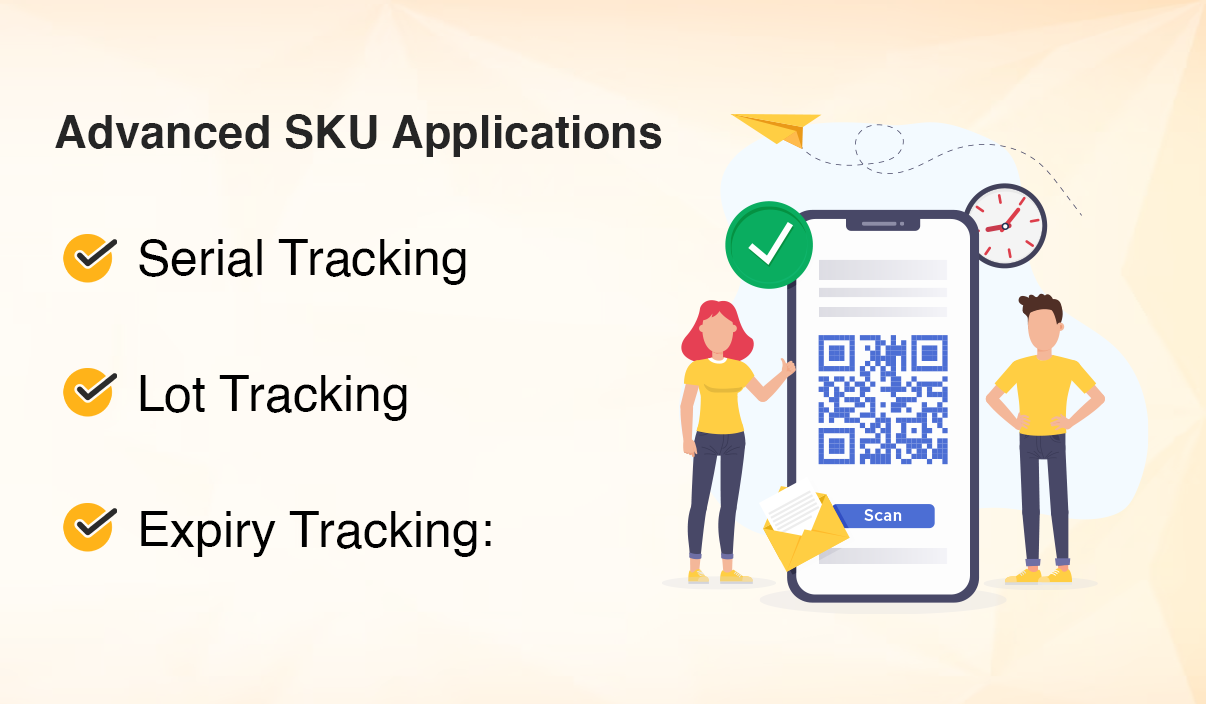

Advanced SKU Applications

While core inventory management remains the primary function of SKUs, some businesses utilize them for additional purposes:

- Serial Tracking: For high-value items or products with unique characteristics, businesses might assign unique SKU codes to each individual unit. This allows for granular tracking of specific items throughout the supply chain.

- Lot Tracking: In some industries, tracking inventory by batches or lots is crucial. SKUs can be designed to incorporate information about the production lot, facilitating product recalls or identifying quality control issues within specific batches.

- Expiry Tracking: For perishable goods or products with expiration dates, SKUs can be used to encode expiry information. This allows businesses to prioritize older stock and minimize the risk of selling expired products.

Conclusion

SKU numbers might seem like a simple string of characters, but they hold immense importance in the world of business. By serving as unique product identifiers and facilitating efficient inventory management, they contribute significantly to a business’s success. Whether it’s preventing stockouts, simplifying product identification, or providing valuable sales insights, SKUs play a crucial role in keeping businesses organized, efficient, and ultimately, customer-satisfied.