Effective warehouse management is the need of today. It is an ongoing cycle that never ends as long as you run a business.

The more your business grows, the more you need a software system to automate the management process to save time and money. After all, you have a large inventory to handle big orders that come in. You will need to spend more time inventory replenishment and organizing your warehouse, which is manually impossible.

Thus, the smart WMS system is key to optimizing the warehouse inventory management process. It stores inventory more efficiently to implementing automation and other tools that help reduce manual work, human error, and overall costs.

Here, in this blog, we will learn what Smart Warehousing is. Plus, know why warehouse inventory management is important, what are industry best practices you can apply, and how useful it is to cut costs and optimize inventory.

What is a Warehouse Management System (WMS)?

Today’s economy is dynamic, omnichannel, and based on consumers buying patterns. Now, consumers are technology freaks and have no time to waste in long billing queues. They attract more to the system that allows them to buy anywhere, fulfill anywhere, and return anywhere. In order to be able to meet this need, businesses need warehouse management system support that can respond quickly and optimize order fulfillment.

A warehouse management system (WMS) manages supply chain fulfillment operations from the distribution centre to the store shelf. It enhances visibility across a business’s entire inventory and benefits the company with stock tracking and monitoring.

It gives businesses an idea to maximize their space/resource usage without stock wastage/expiry matters. WMS accelerates global supply chain processes, including distribution, manufacturing, asset-intensive, and service businesses.

Areas, where warehouse automation can improve operations, include:

- It reduces the unnecessary cost resulting from operating expenses and errors.

- It eliminates manual processes.

- It monitors stock units through the tracking feature.

- It maximizes warehouse space utilization, layout, and flow.

- It gives business accuracy by using barcode scanners, shelf management, and multiple payment methods.

- It protects the assets, brand, and reputation of the company with customers and partners.

- It increases the efficiency and productivity of human resources.

Why warehouse management is important?

The top reason customers show disinterest in your business and stop buying with you is inefficient warehouse operations. This can lead to long waits and inconveniences in business.

Customer retention is directly proportional to warehouse efficiency. When your warehouse efficiency reduces, your customer retention rate will also decrease. This way, it is essential that you have a WMS management system.

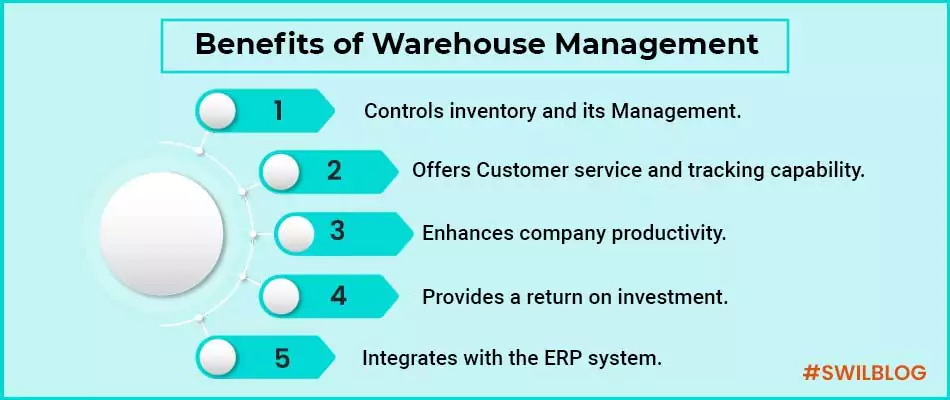

Below are five reasons to consider a Warehouse Management System (WMS).

It controls inventory and its management.

WMS management system automates all of your warehouse activities by controlling inventory levels, improving order fulfillment, and reducing order achievement time. WMS comes with a tracking feature that helps in monitoring even the lowest level of details for better order fulfillment and inventory accuracy. It provides quick, accurate reporting to respond rapidly to their customers’ demands without worrying about expired product delivery.

It offers customer service and tracking capability.

Customers’ buying experience depends upon how effectively and quickly you serve their demanded items. Warehouse management gives business owners a real-time visualization of product availability.

It will let you know whether the ordered products are in stock in real-time. Also, offer pre-alerts for out-of-stock products and expiry products so that you can control the amount of stock. It helps businesses enhance customer service and makes it easier to organize and track shipments through automation. This warehouse automation, up-to-date information, and real-time tracking all lead to better accuracy and happier customers.

It enhances company productivity.

A business warehouse plays a vital role in ensuring that your business runs smoothly and meets its productivity goals. Having an efficient warehouse management system adds efficiency, consistency, and quality control to the entire business process. This allows the goods to be transported to the warehouse at maximum speed and provides a smooth fulfillment. In this way, it increases the productivity of the company.

It provides a return on investment.

The right warehouse management system has the potential to improve your business sales. It maintains the stocks and keeps a close watch on their expiry date and availability so that no customer gets unsatisfied. Thus, it makes customers happy and increases profits. Therefore, it brings accuracy to customer inquiries and simplifies customer support.

It integrates with the ERP system.

A warehouse management system integrates with your existing business management system to give you various business benefits, such as billing, accounting, reporting, GST filing, and more. Thus, the WMS solution is developed according to your needs through ERP integration.

Ways to Cut Costs and Increase Warehouse Efficiency

Undoubtedly, a warehouse management system (WMS) facilitates businesses with features that cut costs and increase warehouse efficiency. It enables automation in the warehouse and reduces the time/cost spend on repetitive, time-consuming, or complex tasks.

Optimize Warehouse Storage With Shelf Management

Customers always demand personalization and want to get their desired product in the shortest possible time.

The warehouse management system works efficiently to optimize the inventory storage system. It comes with shelf management, which significantly increases storage as well as productivity and performance. It completely changed the way you manage your stocks and their delivery.

Give customers a way to get quick delivery

No retailer wants to miss out on sales opportunities, delivery failures just because their storage facility is in a mess.

The warehouse management system allows the business management to reduce warehouse costs and utilize those resources to fulfill the quick order delivery. It determines-

- How much space do your stocks need?

- Create a good layout for it

- Use barcode system

- Categorized non-essential or essential product lists

- Automate daily activities

- Trained staff for quick delivery & more

Improve order handling

One of the most significant considerations of any business is to fulfill the order more efficiently and quickly. With a warehouse management system, you get a solution to process the order in a more systematic and informed way. You know where your order is, get a real-time update on order availability, and more.

Based on the product orders, the system provides an easy way to get them from the warehouse. This dramatically reduces the time it takes to run and find a product. This way, you ensure your business budget and works according to that.

Upgrade Mobile Technology In Your Warehouse

It is a well-known fact that technology can improve efficiency and increase order handling speed. Now, businesses can switch to B2B/B2C mobile apps to offer their customers and vendors a way to order and pay quickly. Also, you get details of the product by scanning the barcode/ QR code via mobile technologies to get maximum benefits.

Easy Inventory Review Process

WMS offers easy inventory monitoring by enabling a real-time update feature. It uses data to review your inventory. It optimizes your inventory and identifies the inventory that’s not moving or moving so fast. This way, you will quickly get-

- Average days to sell inventory

- Inventory turnover rate of products

- return on investment

- How long will you keep the product?

Review Stock Replenishment Practices

You can enhance your inventory operations with WMS management system. It works for you as a full-time inventory controller. It helps in automating the processes. By setting periodic automatic replenishment levels in your inventory, you can create triggers for low inventory to ensure that more products are ordered. In this way, you can work out the damage.

Audit Packaging for Products and Shipment

Order fulfillment involves a lot of wastage. When dealing with different products, you must have a system that gives you the proper management with minimum cost. This shows you many opportunities to make packaging more efficient and create a friendly experience for customers.

Standardize and Audit Your Workflows

You get automated workflows through a warehouse management system. This allows you to monitor and ensure that each employee performs within the same standards.

Workflow is essential to complete tasks and improve them and make your warehouse more efficient. This will increase the workflow efficiency of your business, allow you to keep a close eye on the work of employees, and improve each of their tasks.

Role of SwilERP to reduce Operating cost

The discussion above can help you improve the efficiency of your warehouse, cut unwanted costs, and optimize inventory based on your business needs.

SwilERP is an all-in-one software capable of solving all major business issues. This can help you determine bottlenecks and find opportunities to improve warehouse efficiency. It includes all the possible features that keep the business away from any hindrance.

It implements an all-in-one WMS system and continuously monitors KPIs and performance. It gives you a competitive advantage, makes your business management plan with current market trends. It lowers costs and revamps your warehouse operations.

If you are looking for WMS management system software, you can consider SwilERP, the most integrated WMS in the market. For more information, please visit our website or call our customer care team.