What is purchasing management?

Purchasing management is the strategic approach to acquiring goods and services for a business or organization. It entails supervising every step of the procurement procedure, from determining the demand for a good or service to choosing reliable suppliers, drafting contracts, and handling the payment and delivery procedures. The primary goal of purchasing management is to ensure that the required materials, supplies, and services are obtained at the right time, in the desired quality, and at the most favorable cost.

Everything from determining a need for your production line to negotiating the best price with a dependable supplier is done with precision to ensure a seamless flow of materials. In the end, it all comes down to scheduling appropriately, guaranteeing quality that satisfies your requirements, and controlling expenses.

Read Also : What is procurement management?

Purchasing management example

Consider a manufacturing company that produces various electronic devices, such as smartphones, tablets, and laptops. To guarantee a consistent supply of the parts, raw materials, and machinery needed for the production process, the buying management team is essential.

One of the primary responsibilities of the purchasing team is to research and identify potential suppliers for the various components and materials needed. For this study, suppliers are rated according to several factors, such as product quality, price, delivery time, and dependability. The team makes sure all suppliers satisfy the company’s high standards by carefully reviewing their specs, certifications, and performance history.

Once potential suppliers have been identified, the purchasing team enters into negotiations to secure favorable terms and conditions. Price, terms of payment, delivery dates, and any extra services or warranties that may be provided may all be discussed in this context. Having solid ties with suppliers while negotiating effectively is crucial to getting the best deals.

Another critical aspect of purchasing management is monitoring inventory levels. To anticipate future needs, the team keeps a constant eye on the stock levels of different materials and components. To ensure a constant supply without excessive hoarding or stockouts, they use inventory management systems and forecasting tools to schedule orders at the best possible moment.

The purchasing team adheres to specified procedures and approval processes when placing purchases. They produce purchase orders that list the precise goods needed, their quantities, the dates of delivery, and other pertinent information. These purchase orders are then communicated to the respective suppliers, initiating the procurement process.

Throughout the entire process, the purchasing team coordinates closely with the production department to ensure timely delivery of the purchased items. They track shipments and deal with any possible delays or disruptions in collaboration with suppliers and logistical companies. Collaboration and effective communication are essential to preserving a productive workflow and preventing expensive downtime.

The purchasing staff might also be in charge of recycling or disposing of extra or outdated products in addition to overseeing the incoming supply chain. This would support the business’s cost-cutting and environmental initiatives.

The team guarantees that the manufacturing company has access to the resources it needs to develop high-quality electronic gadgets while lowering costs and upholding solid connections with dependable suppliers by skillfully managing the purchase process.

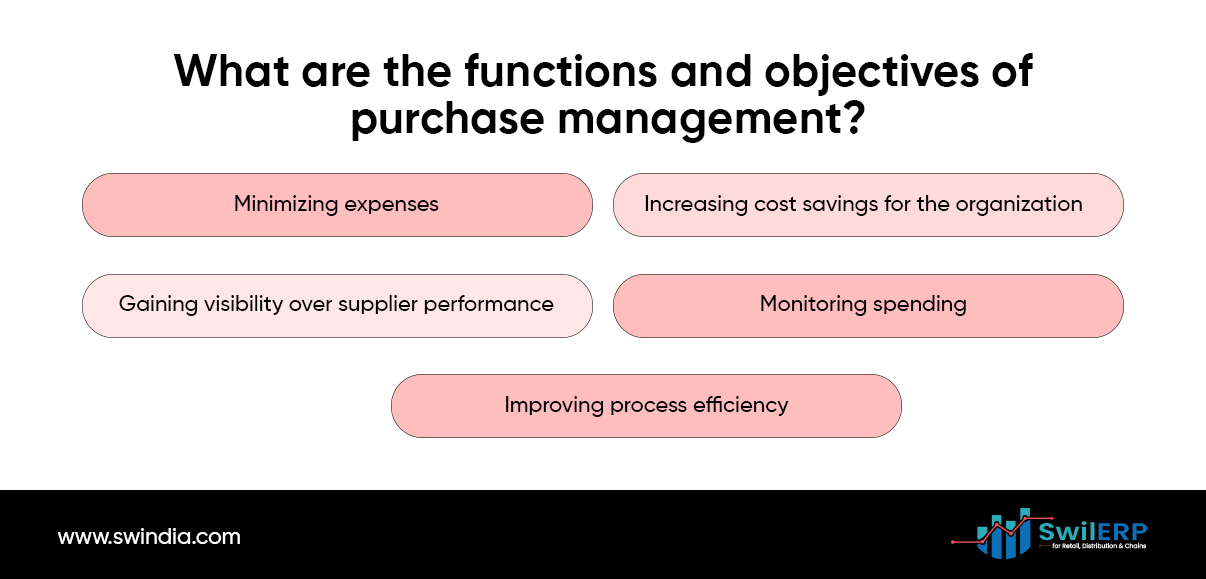

What are the functions and objectives of purchase management?

The primary functions and objectives of purchase management are as follows:

Minimizing expenses

One of the core objectives of purchase management is to reduce the overall costs associated with acquiring goods and services. This includes finding ways to reduce costs, negotiating better prices with suppliers, and putting plans in place to cut down on waste and pointless spending.

In practice, this translates to tasks like meticulously reviewing purchase requisitions to ensure only essential items are ordered, and exploring alternative suppliers or bulk discounts to find the best value. Additionally, implementing clear purchasing policies and approval workflows can help prevent maverick spending and ensure all purchases are aligned with company needs.

Increasing cost savings for the organization

Closely related to minimizing expenses, purchase management aims to generate substantial cost savings for the organization. This can be accomplished by using economies of scale, strategic sourcing, bulk purchasing, and efficient supplier selection.

Businesses may find and cut down wasteful expenditure by putting in place a strong buy management system. Imagine a scenario where you can automate supplier comparisons to consistently find the most competitive prices. Furthermore, you can streamline logistics and possibly unlock bulk discounts by consolidating purchases with a smaller number of trustworthy providers thanks to strategic sourcing. You can make well-informed decisions that result in significant cost savings for your company with this all-inclusive approach to procurement.

Gaining visibility over supplier performance

Purchasing management involves evaluating and monitoring the performance of suppliers. This entails evaluating their capacity to fulfill contractual duties, deadlines for delivery, and quality requirements. Organizations may make educated judgments and take early measures to solve possible problems by having visibility over the performance of their suppliers.

Traditionally, tracking supplier performance often meant wading through emails, spreadsheets, and phone calls. On the other hand, real-time insights into critical data like defect rates, purchase order history, and on-time delivery rates are available with SwilERP’s unified platform. This enables you to pinpoint areas in need of development and work together productively with suppliers to guarantee a seamless and successful supply chain.

Monitoring spending

Purchase management helps organizations track and monitor their spending patterns related to the procurement of goods and services. This allows for better budgeting, forecasting, and the identification of areas where cost optimization measures can be implemented.

Purchase management gives organizations the ability to see spending patterns in real-time and make wise decisions. Consider being able to see patterns in particular categories, such as raw materials or office supplies. This fine degree of specificity makes budgeting and forecasting more precise, limiting waste and guaranteeing effective resource allocation. Finding areas where expenditure is usually high may also provide an opportunity to negotiate better prices with suppliers or receive bulk discounts.

Improving process efficiency

Purchase management seeks to improve overall efficiency by rationalizing the procurement procedure. This may entail standardizing processes, automating some jobs, and getting rid of redundant or pointless steps.

In practice, this might look like automating purchase orders, setting up electronic approvals, or consolidating vendor lists. These steps can significantly reduce processing time and paperwork, allowing your team to focus on strategic sourcing and supplier relationships.

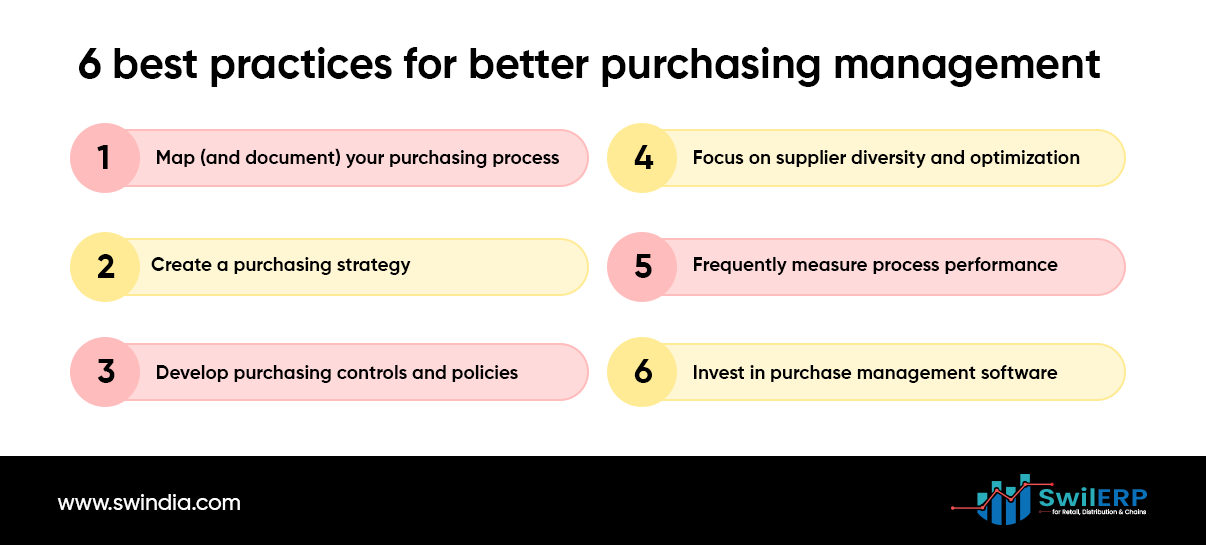

6 best practices for better purchasing management

To maximize the benefits of purchasing management, organizations should adopt the following best practices:

1. Map (and document) your purchasing process

Start by thoroughly understanding and documenting your organization’s current purchasing process. Determine every step that needs to be done, from the request to the payment, and search for ways to streamline or enhance the procedure. This process mapping can be done in cooperation with others! Involve coworkers from other departments, such as receiving, finance, and procurement, who are involved in the purchasing cycle. You can find bottlenecks and redundancies by recording each step and its owner. To better visualize the process and identify key points, think about drawing a flowchart.

2. Create a purchasing strategy

Develop a comprehensive purchasing strategy aligned with your organization’s overall objectives. This strategy should outline guidelines for supplier selection, negotiation tactics, cost-saving measures, and performance evaluation criteria. Here’s how to craft a comprehensive strategy tailored to your organization:

1. Supplier Selection:

Look for vendors with a proven track record of quality, reliability, and responsiveness. Examine their track record for customer service, financial soundness, and reputation in the business. To guarantee a smooth integration with your operations, take into account variables like lead times and geographic location.

2. Negotiation Tactics:

Collaboration is key. Communicate your needs and expectations while understanding the supplier’s perspective. By negotiating parameters related to pricing, payment dates, and volume discounts, concentrate on creating a win-win situation.

3. Cost-Saving Measures:

Consolidate purchases with fewer, high-performing suppliers to leverage economies of scale. Explore bulk discounts and negotiate extended payment terms when financially secure. Standardize frequently used materials and equipment to simplify ordering and potentially reduce costs.

4. Performance Evaluation Criteria:

Track key metrics like on-time delivery rates, product quality, and responsiveness to inquiries. Schedule regular performance reviews to identify areas for improvement and ensure suppliers are meeting your needs.

3. Develop purchasing controls and policies

Implement clear purchasing controls and policies to ensure consistency, transparency, and compliance throughout the procurement process. These guidelines ought to cover matters like supplier management, ethical behavior, and approval hierarchies.

By outlining approval hierarchies, you can define spending limits for different employee levels. This guarantees that people with the necessary financial oversight evaluate and approve larger purchases. Additionally, establishing clear guidelines for ethical conduct during supplier interactions prevents conflicts of interest and fosters trust within the purchasing process. Ultimately, putting in place a good supplier management plan enables you to forge strong bonds with dependable suppliers, which may result in more favorable terms and higher-quality products.

4. Focus on supplier diversity and optimization

Cultivate a diverse and optimized supplier base to mitigate risks, foster competition, and improve overall value. Make sure your supplier connections are in line with the objectives and demands of your company by regularly reviewing and evaluating them.

Think of your network of suppliers as an ecosystem. Variety fosters the health of an ecosystem. Using a variety of providers decreases your reliance on any one source, making you less susceptible to interruptions or changes in pricing. Your company may benefit from lower prices and better services as a result of the supplier competition.

Regularly assess your supplier relationships. Ask yourself: Do their offerings still align with your current needs and future goals? Are there new suppliers emerging who could provide a better fit? You can be confident you’re getting the most out of your supplier network with this continuous assessment.

5. Frequently measure process performance

Regularly monitor and measure key performance indicators (KPIs) related to purchasing management. Metrics including cost reductions, lead times, supplier performance, and process cycle times can be included in this. Make data-driven decisions by using these indicators to pinpoint areas that want improvement.

You can have a clear picture of how your purchasing process works by monitoring these KPIs regularly.

Think of it like checking the instruments on a long journey – regular monitoring allows you to identify potential issues early on, like rising costs or delays with suppliers. This helps you to maintain the efficiency of your purchase process by allowing you to make well-informed modifications and course corrections.

You can be confident you’re making the most of your purchasing power with this data-driven method. You can check to see if you’re getting the greatest deals, find areas where lead times can be cut, and make sure that getting the resources you need has been done effectively overall.

6. Invest in purchase management software

Consider implementing specialized purchase management software to automate and streamline various aspects of the procurement process. Tasks like spend analysis, contract administration, supplier communication, and requisition management can all benefit from the use of these technologies.

Consider implementing purchase management software to simplify and organize your procurement process. These tools act like digital assistants, helping you manage purchase requests from different departments, communicate clearly with suppliers, keep track of contracts, and analyze your spending habits. This can save you significant time and effort by automating repetitive tasks and ensuring all your purchase information is stored in one central location, making it easy to find and reference whenever needed.

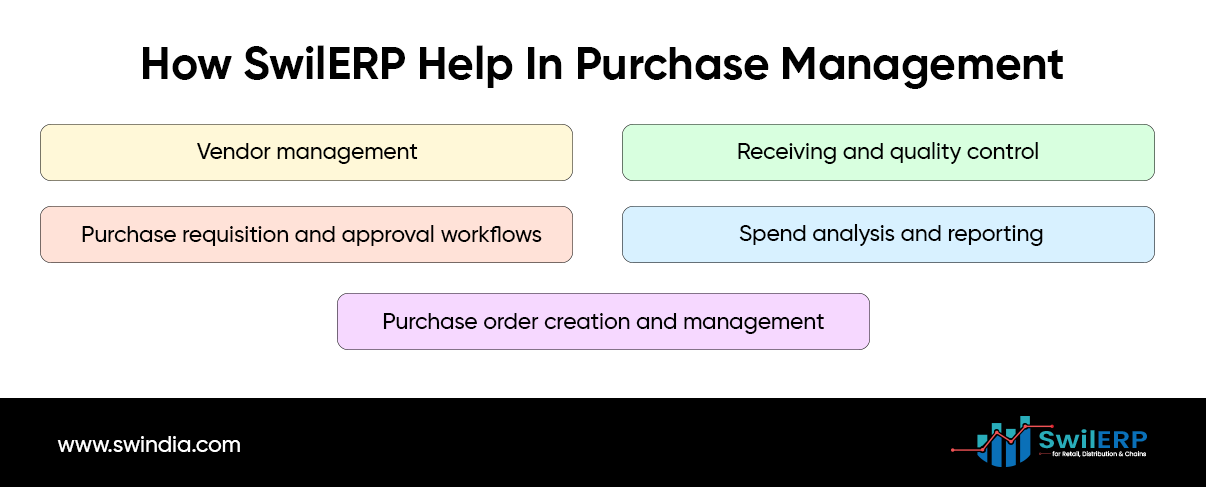

How SwilERP Helps in Purchase Management

SwilERP is a comprehensive enterprise resource planning (ERP) software with strong buying management features. Organizations may enhance overall operational efficiency, optimize expenses, and handle procurement procedures more skillfully using SwilERP.

The purchase management module of SwilERP offers a unified platform for tracking deliveries, maintaining supplier relationships, generating and approving purchase orders, and keeping an eye on expenditures. It provides attributes like:

– Vendor management:

Maintain a comprehensive database of suppliers, their contact information, and performance records.

– Purchase requisition and approval workflows:

Streamline the process of requesting and approving purchases, ensuring proper authorization and compliance.

– Purchase order creation and management:

Generate and track purchase orders, including revision control and integration with inventory management.

– Receiving and quality control:

Record the receipt of goods and perform quality checks, facilitating timely payments and inventory updates.

– Spend analysis and reporting:

Generate detailed reports and analytics on purchasing activities, costs, and supplier performance, enabling data-driven decision-making.

Let’s delve into a practical scenario. Imagine you need to order new printer cartridges. SwilERP allows you to easily find a reliable vendor in your database, complete with contact details and past purchase history. You can then submit a purchase request electronically, specifying the exact type and quantity of cartridges needed. The right person can be contacted to approve this request, guaranteeing that the necessary authorization is obtained before any order is placed.`

SwilERP then guides you through creating a purchase order, a formal document sent to the vendor that outlines the agreed-upon details of the purchase. Included in this are the particular goods, their amounts, costs, and the anticipated delivery date.

With everything clearly defined, there’s less room for misunderstandings and delays.

Once the order is placed, SwilERP helps you track its progress. You can see when the vendor ships the items and receive notifications when they arrive. This allows you to verify the delivery matches the purchase order and update your inventory records accordingly.

SwilERP also provides insightful reports on your purchasing activity. You can examine how much you’re spending on various supply categories, spot patterns, and evaluate vendor prices. You may be able to negotiate better prices with suppliers and make more educated judgments about your future purchases with the use of this useful information.

By leveraging SwilERP’s purchase management capabilities, organizations can gain better visibility and control over their procurement processes, leading to increased cost savings, improved supplier relationships, and enhanced operational efficiency.