One of the biggest problems businesses have in the business sector is the build-up of outdated inventory. Often known as “dead stock” or “excess inventory,” this problem can seriously impair a business’s capacity to make money, expand, and prosper. Obsolete inventory refers to products or materials that are no longer in demand, outdated, or have lost their market value. Retaining these goods reduces cash flow and earnings since it takes up important capital and adds needless storage expenses. Maintaining a healthy cash flow, making the most use of available resources, and being competitive in the market all depend on firms managing their outmoded inventory effectively.

What is Obsolete Inventory?

Obsolete inventory, also known as dead stock or excess inventory, refers to products or materials that have lost their market value due to various reasons. These items may have become obsolete due to changes in customer preferences, technological advancements, or the discontinuation of product lines. Synonyms for obsolete inventory include unsaleable merchandise, overstocked goods, and outdated products. Whatever word is applied, out-of-date inventory costs companies a lot of money since it wastes money, takes up space, and requires ongoing storage expenses while producing no income.

Causes of Obsolete Inventory:

Several factors can contribute to the accumulation of obsolete inventory in a business. One of the primary causes is a change in customer preferences or trends. Products that were previously popular may become outdated when customer wants and tastes change, creating excess inventory. Furthermore, current products may become antiquated due to technological improvements, which would decrease their marketability.

Poor demand forecasting is another significant contributor to obsolete inventory. When businesses fail to predict customer demand accurately, they may overstock certain products, leading to an excess of unsold items. Similarly, discontinued product lines or a failure to phase out older models can result in a buildup of obsolete inventory.

Alright, so we’ve talked about what obsolete inventory is, but how does it end up piling up in businesses? Well, there are a few main reasons, and they’re not too complicated to understand.

One of the biggest culprits is our good friend, changing customer preferences. You know how fads and trends come and go, right? Well, the same thing happens with products. One minute, everyone’s going crazy for a certain toy or gadget, and the next, they’ve moved on to something new. It’s like how you might have loved a certain cartoon when you were a kid, but now you think it’s kind of lame.

When customer tastes change like that, it can leave businesses with a whole bunch of products that nobody wants anymore. Imagine a company that makes those trendy fidget spinners from a few years ago. One minute, they couldn’t keep them on the shelves, and the next, nobody cared about them anymore. That’s a recipe for obsolete inventory!

Another big reason is technological advancements. We all know how quickly technology moves these days. Remember when flip phones were the coolest thing ever? Now, they’re practically ancient history. When new and improved technology comes out, it can make older products seem outdated and unwanted. That leaves businesses stuck with inventory that’s become obsolete almost overnight.

But it’s not just changing trends and technology that can cause this problem. Sometimes, businesses simply make poor predictions about how much of a product they’ll need. They might think a certain item is going to be a huge hit, so they order a ton of it. But if their prediction is way off, and the product doesn’t sell as well as they expected, they’re left with a massive excess of inventory that nobody wants.

It’s kind of like when you were a kid, and your parents bought you way too much of a certain toy because they thought you’d love it, but you ended up playing with it once and never touching it again. That’s the kind of situation businesses want to avoid, but sometimes they just can’t predict demand accurately.

Another scenario that can lead to obsolete inventory is when companies decide to discontinue a product line altogether. Maybe they’re revamping their offerings or shifting their focus to something else. Whatever the reason, if they stop making a certain product, any remaining inventory of that product instantly becomes obsolete.

And finally, let’s not forget about good old-fashioned disorganization and inefficiency. If a business doesn’t have a good system for keeping track of its inventory levels and sales, it’s easy for things to slip through the cracks. They might end up holding onto products that nobody’s buying anymore simply because they weren’t paying close enough attention.

It’s kind of like having a messy closet or toy box when you were a kid. You might have had some cool stuff buried in there that you’d forgotten about, but it was just collecting dust because you didn’t even know it was there.

So, there you have it – the main reasons why businesses end up with piles of obsolete inventory. From changing trends and technology to poor forecasting and inefficient management, there are plenty of ways for this problem to creep up on companies if they’re not careful. But don’t worry, we’ll talk about how they can tackle this issue a little later on.

Read Also: Inventory Management: Why It Matters and How It Gets Tricky, Explained

The Cost of Obsolete Inventory:

The impact of obsolete inventory on a business’s bottom line cannot be overstated. One of the most significant costs associated with obsolete inventory is the lost revenue due to unsold items. Products that sit idle on shelves or in warehouses represent missed opportunities for generating sales and profit.

Additionally, businesses incur storage costs for these unsold products. Renting or maintaining warehouse space to store obsolete inventory can be a significant financial burden, especially for small to medium-sized enterprises.

Obsolete inventory can also lead to potential write-downs on the balance sheet. As these items lose their market value, businesses may be required to adjust their asset values accordingly, impacting their financial statements and potentially affecting their ability to secure financing or attract investors.

Furthermore, outmoded inventory can make a company’s cash flow very difficult. Since the money could have been used to settle debts or invest in more profitable sections of the company, the money tied up in these unsold products constitutes a large opportunity cost.

Identifying Obsolete Inventory:

Identifying obsolete inventory is the first step towards effective management. Business owners can take several actionable steps to identify obsolete inventory within their operations:

1. Analyze sales data:

Regularly reviewing sales data can help identify slow-moving or unsold items. Products with little to no sales over an extended period may be considered obsolete.

2. Monitor product lifecycles:

Keeping track of product lifecycles is crucial, as it can help identify items that are nearing obsolescence. Businesses can better manage their inventory levels and prevent acquiring surplus stock by forecasting the end of a product’s lifecycle.

3. Conduct regular inventory audits:

Physical verification of inventory levels through regular audits can help identify discrepancies between actual stock levels and recorded data. This procedure can reveal out-of-date inventory that was possibly missed.

4. Communicate with salespeople and customers:

Maintaining open communication with salespeople and customers can provide valuable insights into demand trends and potential shifts in preferences. This information can help businesses identify products that may soon become obsolete.

Read Also: E-commerce Inventory Management: A Complete Guide for Online Retailers

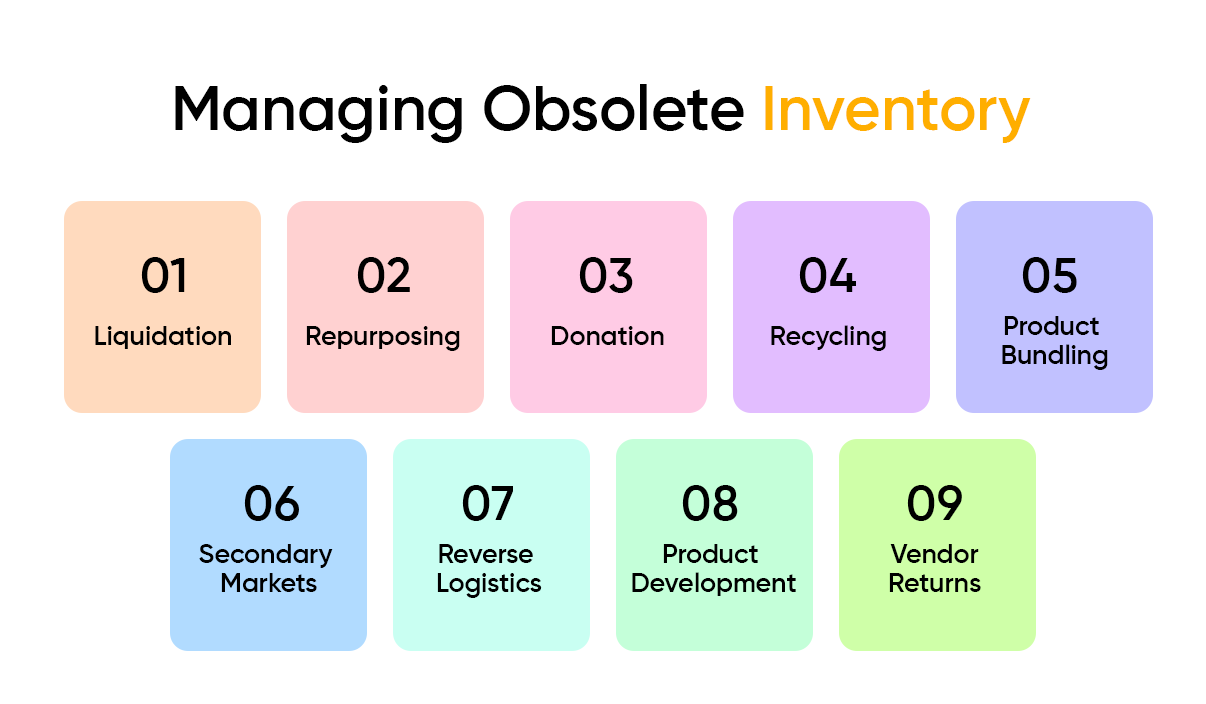

Managing Obsolete Inventory:

Once obsolete inventory has been identified, businesses need to implement strategies to manage and mitigate its impact. Several approaches can be considered:

1. Liquidation:

One of the most common methods for dealing with obsolete inventory is liquidation. This entails using sales or clearance events to sell the merchandise at a reduced cost. This strategy might lead to smaller profit margins, but it gives companies a way to make some money off of goods that would otherwise go unsold.

2. Repurposing:

In some cases, obsolete inventory can be repurposed for a different use. This may involve modifying the product or repackaging it for a different market segment. Repurposing can help businesses extract additional value from their existing inventory.

3. Donation:

For products that cannot be sold or repurposed, businesses may consider donating them to charities or organizations that might find them useful. This approach not only helps clear obsolete inventory but also provides a tax benefit and contributes to social responsibility efforts.

4. Recycling:

In cases where products or materials can be broken down and recycled, businesses may opt to recycle obsolete inventory.

5. Product Bundling:

Combining obsolete items with fast-selling products can help clear out inventory by incentivizing customers to purchase bundled items at a discounted price.

6. Secondary Markets:

Exploring secondary markets like online marketplaces, auction sites, or speciality retailers can provide alternative channels to sell obsolete inventory.

7. Reverse Logistics:

Implementing a reverse logistics strategy can help businesses manage returns and excess inventory efficiently, potentially reducing the amount of obsolete stock.

8. Product Development:

Repurposing obsolete inventory components or materials for new product development can help businesses innovate and create value from otherwise stagnant inventory.

9. Vendor Returns:

Negotiating with suppliers for returns or exchanges on obsolete inventory can help mitigate losses and free up warehouse space for more profitable items.

Those are the main strategies businesses can use to deal with their obsolete inventory. Each one has its pros and cons, and the best approach really depends on the specific situation. Maybe a combination of a few different methods would work well.

The important thing is not just letting all that obsolete stuff pile up forever. It’s a waste of space, it’s costing you money in storage fees, and it’s just plain inefficient.

It’s all about being proactive and creative in finding solutions. Because let’s be real – nobody wants a warehouse full of junk that’s just gathering dust and doing nothing but draining your resources. It’s time to put that obsolete inventory in its place and move on to bigger and better things!

Preventing Obsolete Inventory:

While managing existing obsolete inventory is important, businesses should also focus on implementing strategies to prevent future accumulation. Here are some tips for minimizing the risk of obsolete inventory:

1. Implement accurate demand forecasting methods:

Utilizing advanced demand forecasting techniques, such as predictive analytics or machine learning algorithms, can help businesses accurately anticipate customer demand and adjust their inventory levels accordingly.

2. Utilize just-in-time (JIT) inventory management:

The JIT approach involves ordering and receiving inventory only when it is needed for production or sale. This method can help reduce the risk of overstocking and minimize the accumulation of obsolete inventory.

3. Maintain clear communication with suppliers:

Establishing open lines of communication with suppliers is essential for effective inventory management. Businesses should provide clear and timely purchase orders, and address any potential supply chain disruptions promptly.

4. Regularly review product life cycles:

By continuously monitoring product lifecycles and staying informed about emerging trends and technologies, businesses can make informed decisions about discontinuing slow-moving or obsolete items from their product lineup.

Conclusion:

Effective obsolete inventory management is a critical aspect of business success. Identifying and addressing obsolete inventory can help businesses free up valuable capital, reduce storage costs, and improve overall profitability. By implementing the strategies outlined in this guide, business owners can gain better control over their inventory levels, prevent the accumulation of obsolete stock, and maintain a competitive edge in their respective markets.

Remember, proactive inventory management is key to minimizing the financial burden of obsolete inventory. Through consistent analysis of sales data, tracking of product life cycles, audits, and stakeholder communication, organizations may remain ahead of potential problems and make well-informed decisions regarding their inventory management practices.

Embracing effective obsolete inventory management not only enhances financial performance but also promotes sustainability and responsible business practices. By minimizing waste and maximizing resource utilization, businesses can contribute to a more sustainable future while ensuring long-term success and growth.