Maintaining a wholesale distribution company requires you to handle a lot of inventory, complete orders accurately and swiftly, and satisfy consumers. This manual covers five essential procedures that can help you better organize and run your company. You may increase your overall efficiency, order fulfillment, and inventory management by implementing these procedures.

I. Simplifying Inventory Management

A. Implementing inventory management software

Utilizing specialized inventory management software can provide real-time visibility into stock levels, automate reordering processes, and generate reports for informed decision-making. This can help minimize stockouts, reduce overstocking, and improve overall inventory control.

B. Utilizing forecasting techniques to predict demand

Accurately forecasting customer demand is crucial for effective inventory management. Techniques like time-series analysis, regression models, or machine learning algorithms can help analyze historical sales data, identify trends, and predict future demand patterns.

C. Optimizing warehouse layout and picking processes

Organizing your warehouse layout and optimizing picking routes can significantly enhance operational efficiency. Strategies like implementing a well-designed layout, utilizing pick zones, and utilizing picking technologies like voice-directed picking can reduce travel time and improve order accuracy.

D. Establishing clear procedures for inventory control (cycle counts, ABC analysis)

Implementing robust inventory control procedures, such as regular cycle counts and ABC analysis (categorizing inventory based on value and demand), can help identify and address discrepancies, minimize inventory shrinkage, and prioritize the management of high-value and high-demand items.

E. Minimizing stockouts and overstocking

By effectively managing inventory levels, you can minimize the risks of stockouts (which can lead to lost sales and dissatisfied customers) and overstocking (which ties up capital and increases carrying costs). Regularly monitoring inventory levels, setting appropriate reorder points, and adjusting stock levels based on demand forecasts can help strike the right balance.

II. Enhancing Order Processing and Fulfillment

A. Automating order processing tasks

Automating tasks like order entry, validation, and allocation can significantly reduce manual efforts, minimize errors, and increase overall efficiency in order processing.

B. Establishing clear communication protocols for order confirmation and fulfillment

Implementing clear communication protocols with customers, such as order confirmations, shipping notifications, and tracking information, can improve customer satisfaction and reduce inquiries or disputes.

C. Implementing efficient picking and packing procedures

Optimizing your picking and packing processes, including strategies like batch picking, can minimize travel time, reduce errors, and increase productivity.

D. Integrating with shipping carriers for faster delivery times

Establishing partnerships with reliable shipping carriers and integrating their systems with your order management can streamline the shipping process and provide customers with faster delivery times.

E. Providing real-time order tracking for customers

Offering customers the ability to track their orders in real-time can enhance transparency, build trust, and reduce customer service inquiries related to order status.

III. Building Strong Supplier Relationships

A. Negotiating favorable pricing and terms

Building strong relationships with suppliers can provide leverage in negotiating favorable pricing, payment terms, and other conditions that can positively impact your bottom line.

B. Establishing clear communication channels and expectations

Maintaining open and clear communication channels with suppliers is essential for ensuring timely deliveries, addressing issues promptly, and aligning expectations on both sides.

C. Implementing vendor managed inventory (VMI) if applicable

In some cases, implementing a vendor managed inventory (VMI) system, where suppliers manage and replenish your inventory levels based on agreed-upon parameters, can be an effective strategy for inventory management.

D. Promoting collaboration for product development and forecasting

Collaborating with suppliers on product development initiatives and sharing demand forecasts can help ensure a reliable supply of products that meet customer needs.

E. Developing a contingency plan for managing supplier disruptions

Having a contingency plan in place to deal with potential supplier disruptions, such as identifying alternative sources or maintaining safety stock, can help mitigate the impact of supply chain disruptions on your operations.

IV. Optimizing Warehouse Operations

A. Investing in warehouse automation (e.g., conveyors, barcode scanners)

Implementing warehouse automation technologies, such as conveyors, barcode scanners, and automated storage and retrieval systems, can significantly improve productivity, accuracy, and overall efficiency in warehouse operations.

Implementing warehouse automation technologies can significantly improve productivity, accuracy, and overall efficiency. For example, conveyor systems can streamline the movement of goods within the warehouse, reducing manual handling and improving throughput. Barcode scanners and mobile computing devices can automate data capture and eliminate manual data entry errors.

B. Implementing proper space utilization and storage strategies

Optimizing warehouse space utilization through strategies like narrow aisle racking, vertical storage, and proper slotting can maximize available space and improve efficiency in picking and putaway processes.

Optimizing warehouse space utilization is crucial for maximizing storage capacity and improving operational efficiency. Strategies like narrow aisle racking, which allows for denser storage by reducing aisle widths, and vertical storage solutions like mezzanines or multi-level picking modules can significantly increase storage density. Additionally, implementing proper slotting strategies, where products are strategically placed based on factors like demand, pick frequency, and product characteristics, can improve picking efficiency.

C. Enforcing safety protocols and employee training

Ensuring a safe work environment by implementing safety protocols and providing regular training for warehouse staff can help prevent accidents, minimize disruptions, and maintain a productive workforce.

Ensuring a safe work environment is not only a legal and ethical responsibility but also essential for maintaining a productive workforce. Implementing safety protocols, such as proper personal protective equipment (PPE) requirements, safe material handling practices, and emergency response procedures, can help prevent accidents and minimize disruptions. Regular training and safety awareness programs can reinforce these protocols and promote a culture of safety within the workplace.

D. Regularly evaluating and improving warehouse efficiency

Continuously monitoring and analyzing warehouse performance metrics, such as order fulfillment times, picking accuracy, and space utilization, can help identify areas for improvement and implement changes to enhance overall efficiency.

Continuously monitoring and analyzing key performance indicators (KPIs) related to warehouse operations, such as order fulfillment times, picking accuracy, and space utilization, can help identify areas for improvement. Conducting regular operational audits, analyzing workflow processes, and gathering employee feedback can provide insights into inefficiencies and opportunities for process improvements.

E. Outsourcing warehousing to a 3PL (third-party logistics) provider (consideration)

In some cases, outsourcing warehousing operations to a third-party logistics (3PL) provider can be a viable option, especially for businesses that lack the resources or expertise to manage warehousing effectively in-house.

In some cases, outsourcing warehousing operations to a third-party logistics (3PL) provider can be a viable option, especially for businesses that lack the resources or expertise to manage warehousing effectively in-house. 3PL providers specialize in warehousing and distribution services, offering economies of scale, advanced technologies, and specialized expertise that can enhance operational efficiency and reduce costs.

V. Leveraging Technology for Efficiency

A. Utilizing a Warehouse Management System (WMS)

A Warehouse Management System (WMS) is a software solution that can help manage and optimize various warehouse operations, including inventory management, order fulfillment, and labor management, leading to improved productivity and efficiency.

These systems can provide real-time visibility into inventory levels, automate order fulfillment processes, manage labor resources, and integrate with other systems like ERPs or transportation management systems.

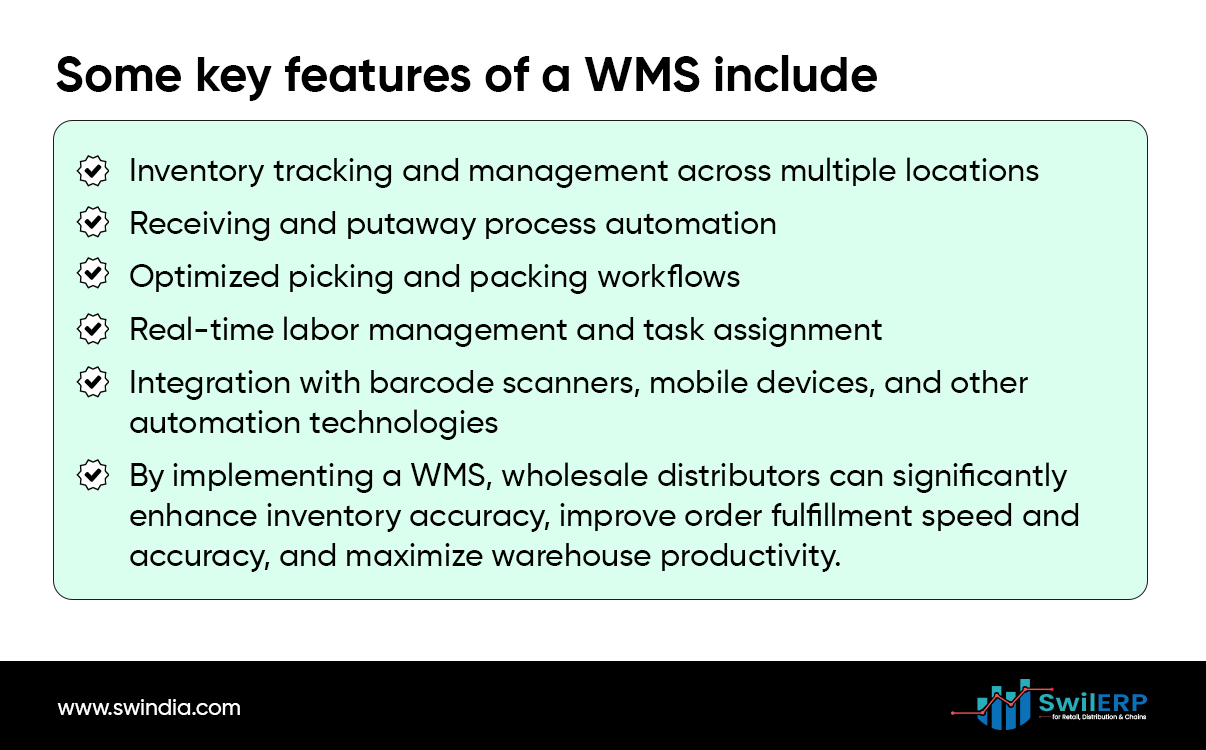

Some key features of a WMS include:

Inventory tracking and management across multiple locations

Receiving and putaway process automation

Optimized picking and packing workflows

Real-time labor management and task assignment

Integration with barcode scanners, mobile devices, and other automation technologies

By implementing a WMS, wholesale distributors can significantly enhance inventory accuracy, improve order fulfillment speed and accuracy, and maximize warehouse productivity.

B. Implementing data analytics to identify operational bottlenecks

Data analytics can be a real game-changer when it comes to simplifying operations and boosting efficiency. By tapping into the wealth of data that flows through systems like warehouse management software, inventory tracking tools, and order processing platforms, businesses can gain invaluable insights into areas where bottlenecks or inefficiencies might be holding them back.

Think about it – you’ve got all this raw information at your fingertips, detailing every step of your processes, from receiving and putaway to picking and shipping. With the right data analytics tools, you can essentially put on a pair of X-ray glasses and see exactly where things might be getting hung up or where processes could be tightened up.

Let’s say you notice a consistent delay in getting orders out the door – by diving into the data, you might uncover that a particular picking workflow or product slotting strategy is causing pickers to waste time criss-crossing the warehouse floor. Armed with that knowledge, you can make targeted adjustments to optimize picking routes, reconfigure your layout, or even implement new technologies like voice-directed picking to streamline the process.

Or maybe you’re seeing higher-than-expected inventory carrying costs – data analytics could reveal inefficiencies in your forecasting or ordering processes, allowing you to fine-tune your inventory management strategies and avoid tying up too much capital in excess stock.

The key here is being able to turn all that raw data into actionable insights that inform smart, data-driven decisions. It’s like having a constant feedback loop, allowing you to continuously identify areas for improvement and make targeted changes to enhance overall operational efficiency.

And the best part? This isn’t some pie-in-the-sky concept – businesses across industries are already leveraging data analytics to gain a competitive edge. By embracing these tools and techniques, wholesale distributors can position themselves at the forefront of operational excellence, driving down costs, boosting productivity, and delivering better service to their customers.

C. Encouraging paperless transactions (e.g., electronic invoices)

Transitioning to paperless transactions, such as electronic invoices and purchase orders, can reduce manual efforts, minimize errors, and improve overall operational efficiency.

Transitioning to paperless transactions, such as electronic invoices, purchase orders, and shipping documents, can significantly improve efficiency and reduce errors. Electronic document management systems (EDMS) can streamline the processing and storage of these documents, eliminating the need for manual data entry and reducing the risk of errors associated with paper-based processes.

Additionally, electronic transactions can facilitate faster communication and collaboration with suppliers, customers, and other stakeholders, improving response times and enabling more efficient decision-making.

D. Automating reporting and data analysis

Manual reporting and data analysis processes can be time-consuming and prone to errors. Think about how much time and effort goes into manually compiling those reports on sales figures, inventory levels, and all those key metrics. It’s a total slog, and by the time you’ve got the report ready, the data’s already getting stale.

But with automated reporting tools, you can essentially set it and forget it. No more waiting around for month-end reports – you can monitor sales trends, track inventory movements, and keep a pulse on those all-important KPIs in real-time.

Imagine having a virtual analyst at your fingertips, crunching through mountains of data from your operations, orders, logistics – you name it. Business intelligence and advanced analytics platforms can spot patterns, identify trends, and surface insights that would be practically impossible to uncover manually. Suddenly, you’ve got a crystal ball into demand fluctuations, operational bottlenecks, and areas ripe for optimization.

The best part? No more relying on gut feelings or anecdotal evidence – with automated data analysis, you’ve got hard data to back up your decisions. Want to tweak your inventory management strategy? The numbers will show you exactly how much safety stock you need for each product line. Trying to streamline fulfillment processes? The analytics can pinpoint exactly where things are getting bogged down.

E. Investing in mobile technology for real-time access to information

Giving warehouse workers mobile devices, such tablets or handheld scanners, can give them instant access to order information, inventory data, and other vital information, facilitating better decision-making and increased operational effectiveness.

Mobile Applications and Integrated Systems

Businesses can further improve productivity and real-time information access by utilizing mobile applications and integrated systems in addition to offering mobile devices for field workers and warehouse staff.

It is possible to create or modify mobile applications that offer an intuitive user interface for a number of functions, including order entry, inventory control, and shipment tracking. Order management platforms, WMSs, and ERPs are examples of backend systems with which these apps can be coupled to provide smooth data flow and current information at all points of contact.

For example, a mobile application for sales representatives could provide real-time access to inventory levels, pricing information, and customer order histories, enabling them to place orders or check stock availability on the go. Similarly, a mobile app for delivery personnel could provide turn-by-turn navigation, customer address details, and signature capture capabilities for proof of delivery.

Integrating these mobile applications with backend systems can streamline processes, reduce manual data entry, and minimize errors, ultimately improving operational efficiency and customer experience.

Cloud Computing and Software-as-a-Service (SaaS) Solutions

Due to its scalability, affordability, and accessibility, cloud computing and Software-as-a-Service (SaaS) solutions are growing in popularity within the wholesale distribution sector.

SaaS solutions, such as cloud-based inventory management, order management, or warehouse management systems, can provide businesses with powerful functionality without the need for extensive hardware investments or on-premises infrastructure maintenance.

Real-time data access and collaboration features are other benefits of cloud-based solutions that allow for easy information sharing between several locations or with external stakeholders like clients or suppliers.

Additionally, SaaS providers typically handle software updates, security patches, and backups, reducing the burden on internal IT resources and ensuring access to the latest features and enhancements.

Wholesale distributors can gain more flexibility, scalability, and cost-effectiveness as well as enhanced operational efficiency and instant access to vital data and insights by implementing cloud computing and SaaS solutions.