Imagine a scenario – your storeroom is overflowing with boxes upon boxes of merchandise. While this might seem like a sign of abundance, the reality can be quite the opposite. A significant portion of that inventory might consist of slow-moving items – products gathering dust instead of flying off the shelves. These slow-movers not only tie up significant capital that could be utilized for additional useful purposes, but they also consume valuable extra room and might become outdated after some time. Efficiently recognizing and handling stagnant inventory is essential for the general well-being of your retail enterprise

What is Slow-Moving Inventory?

Slow-moving inventory refers to merchandise that experiences low sales velocity. These items typically sit on the shelves for extended periods compared to your faster-selling products. The definition of “slow-moving” can vary depending on your industry. For instance, a trendy clothing store might consider an item slow-moving if it remains unsold for a month, while a furniture store might have a different timeframe based on the typical buying cycle for furniture. Regardless of the specific timeframe, the key characteristic of slow-moving inventory is its low sales volume and prolonged storage time.

Read Also: Retail Inventory Management: A Comprehensive Guide for Retailers

Why Slow-Moving Inventory is a Problem

Slow-moving inventory acts like a weight dragging down your business. Here are some key issues it creates:

- Tied-up Capital: The money you invest in unsold inventory is essentially locked away. This money would be more effectively used to fund marketing initiatives, the acquisition of new, in-demand items, or corporate expansion. Slow-moving inventory is a sign of a growth opportunity lost.

- Lost Storage Space: Every product on your shelves occupies valuable real estate. When a significant portion of that space is taken up by slow-movers, it limits your ability to stock faster-selling items that could potentially generate more revenue.

- Risk of Obsolescence: Trends change, and products can quickly become outdated. Fashion styles evolve, technology advances and certain items might have expiration dates. Slow-moving inventory faces a higher risk of becoming obsolete, leading to write-offs and lost revenue.

- Reduced Cash Flow: Slow sales of stagnant inventory translate to slower cash flow. If money stops coming in regularly, it can lead to problems paying your bills on time. You may also run out of needed supplies and products to keep your business going. Additionally, you may miss chances to grow your business in the future. Having a steady flow of money coming in is very important for any business to run properly.

Identifying Slow-Moving Inventory: Key Metrics

To effectively manage your inventory and identify potential slow-movers, it’s crucial to utilize specific metrics. Here are three key indicators:

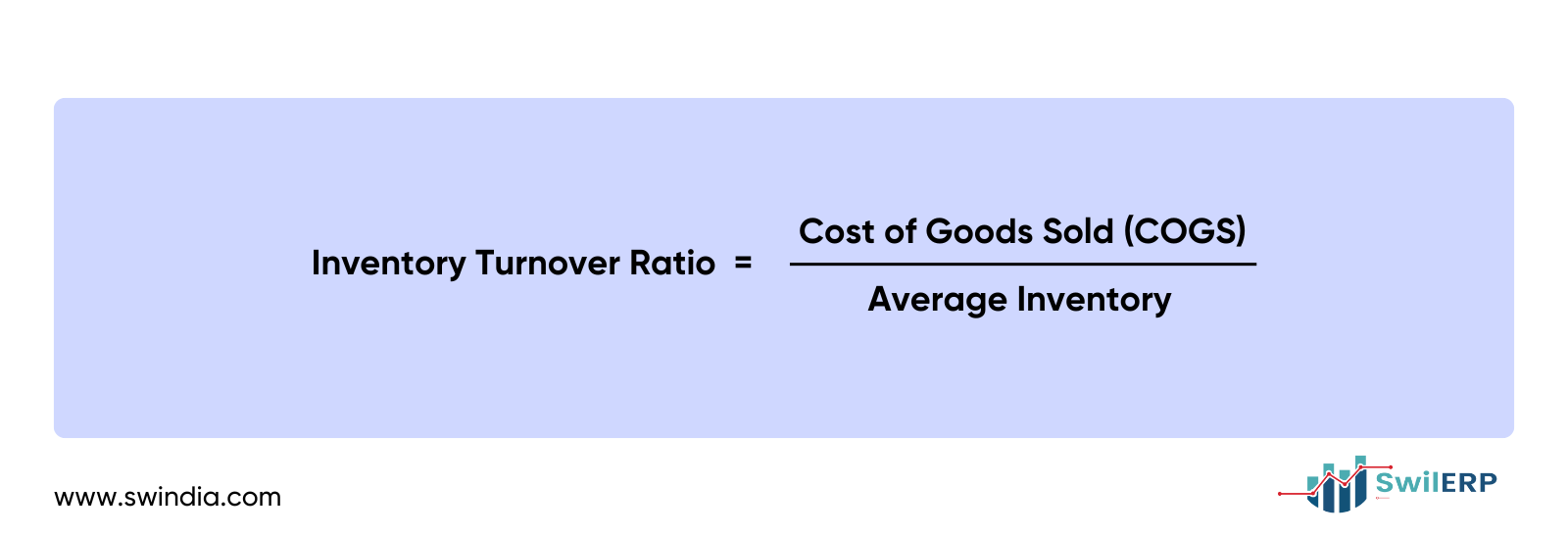

A. Inventory Turnover Ratio:

The inventory turnover ratio measures how efficiently you sell and replace your inventory over a specific period. A high ratio indicates a healthy inventory turnover, while a low ratio suggests potential slow-moving items.

How to Calculate It: Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

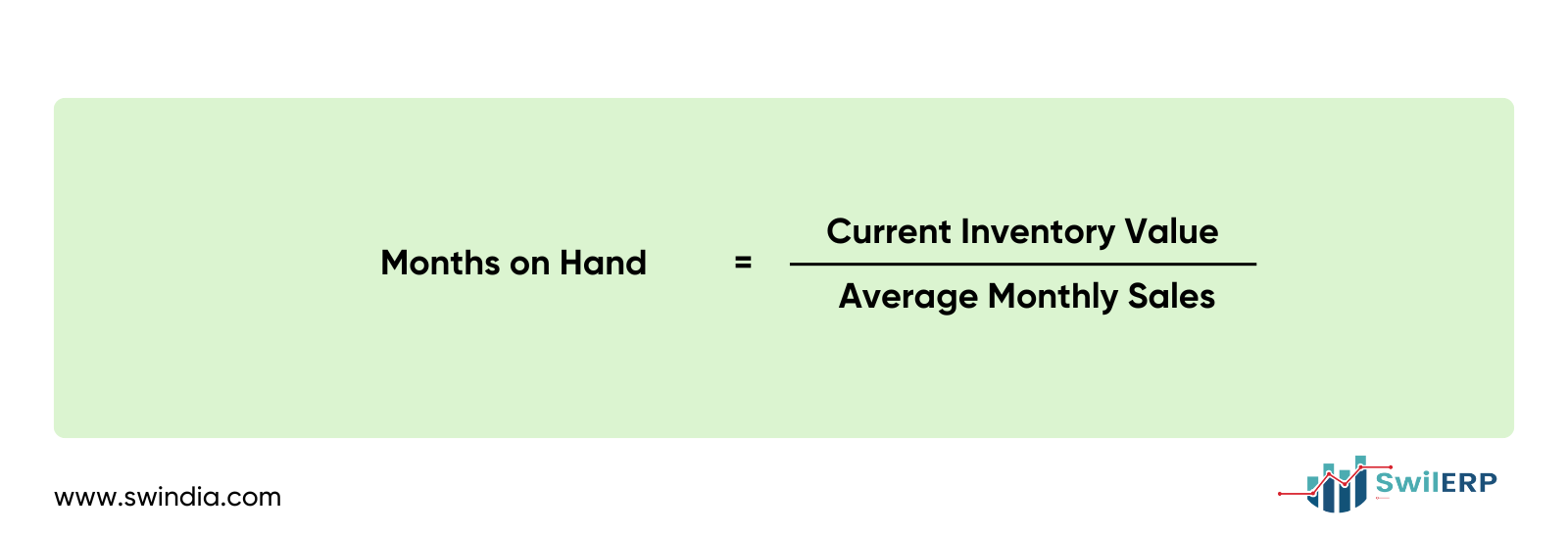

B. Months on Hand:

This metric indicates the average amount of time it takes to sell your entire inventory. A high number of months on hand suggests the presence of slow-moving items.

How to Calculate It: Months on Hand = Current Inventory Value / Average Monthly Sales

C. Unit Purchase Price Trends:

Monitor your unit purchase price trends over time. Stagnant or declining unit purchase prices can be an indicator of slow sales and potential discounting by competitors to clear out similar inventory.

Imagine you buy a particular brand of sneakers for your store at a steady price for a while. Then, one day, the supplier offers them at a discount.If the price tags on your products change, it may mean something is different. By keeping an eye on the prices of your items over time, you can learn useful information about how well those items are selling.

Here’s how it works:

- Track Prices: Regularly monitor the price you pay for each item you buy. Keep a record of past purchase prices for comparison.

- Stagnant Prices: If the price you pay for an item stays the same for a long time, it might indicate that the product isn’t selling as quickly as expected. This could be a potential slow-mover.

- Dropping Prices: A sudden decrease in the unit purchase price from your supplier can be a red flag. This might suggest that the supplier is trying to clear out their own stock of slow-moving items, and it could be a sign that your sales of that product are also slowing down.

- Competitor Discounts: Sometimes, a drop in your purchase price might not be initiated by your supplier directly. If your competitors are discounting similar products to clear out their inventory, it can put pressure on your supplier to lower their prices as well. This may indicate a slowdown in the general demand for that kind of product.

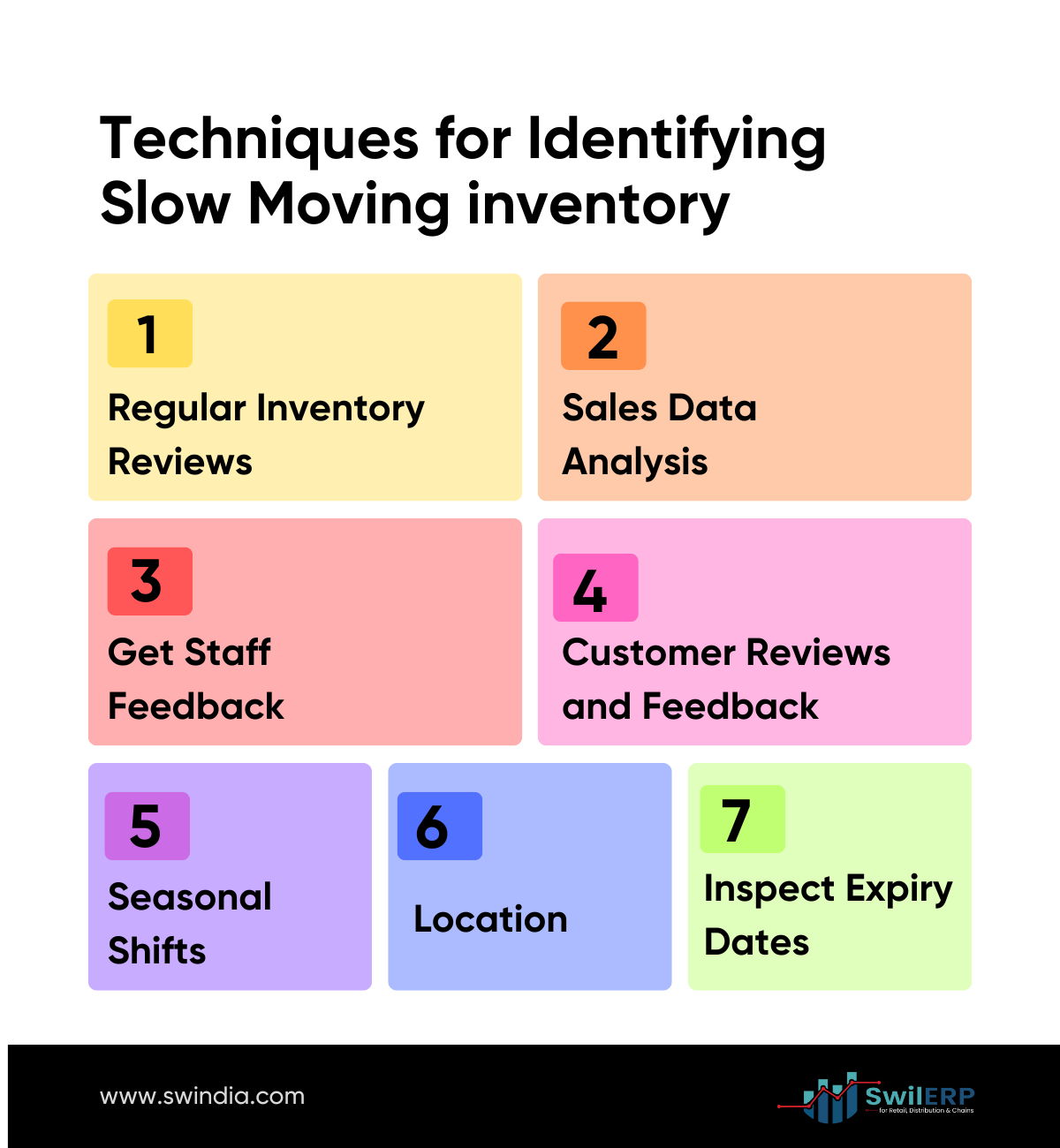

Additional Techniques for Identifying Slow-Movers

In addition to these crucial criteria, the following other methods can assist you in identifying slow-moving inventory:

- Regular Inventory Reviews: Conduct scheduled inventory checks and pay close attention to items gathering dust or showing signs of damage. These can turn out to be slow movers.

- Sales Data Analysis: Regularly analyze your historical sales data to identify trends. Look for products with consistently low sales figures or declining sales patterns. If these products are becoming slow-moving, it may be worth looking into them more.

- Get Staff Feedback: Your employees are on the front lines interacting with customers every day. They could be able to provide insightful information about what things clients are reluctant to buy or seldom inquire about. Encourage open communication with your staff and ask them to share their observations about slow-moving inventory.

- Customer Reviews and Feedback: Pay attention to customer reviews and feedback, both online and in-store. Customers might mention specific products they find outdated, overpriced, or simply not interesting. These remarks may serve as an important indicator if an item is staying on your shelf for an extended period of time.

- Seasonal Shifts: Consider the impact of seasons on buying habits. For example, winter coats might sell briskly in December but gather dust throughout the summer months. Consider seasonal patterns and modify your inventory levels appropriately. Analyze past sales data to identify patterns and anticipate future demand.

- Location: Not all areas of your store are created equal. High-traffic zones near the entrance or checkout might be ideal for showcasing new or fast-selling products. Slower-moving items can be strategically placed on lower shelves or in less prominent locations to free up valuable space in high-visibility areas.

- Inspect Expiry Dates: For products with expiration dates, conduct regular checks to identify items nearing the end of their shelf life. These products become prime candidates for discounts or promotions to avoid them expiring entirely and resulting in lost revenue.

By incorporating these additional techniques alongside the key metrics discussed earlier, you can gain a more comprehensive understanding of your inventory performance and pinpoint slow-moving items with greater accuracy. Remember, a vigilant approach to inventory management is key to a healthy retail business.

Dealing with Slow-Moving Inventory

Once you’ve identified slow-moving inventory, it’s time to take action. Here are some strategies to consider:

Strategies for Handling Slow-Moving Inventory:

- Discounts and Promotions: Run targeted discounts or promotions on slow-moving items to generate interest and encourage sales. This can help clear out stagnant inventory and free up capital.

- Bundling: Bundle slow-moving items with faster-selling products to create a more attractive offering for customers. This can entice them to purchase the slow-mover along with the desired product.

- Reposition or Repurpose: Consider if there are ways to reposition or repurpose slow-moving items. Can they be used for a different purpose or target a different customer segment?

Read Also:Why Omnichannel Inventory Management is Essential: A Complete Guide

Considering Alternatives:

- Returns to Suppliers: In some cases, returning slow-moving inventory to suppliers might be an option, especially if there are return policies in place. This helps reclaim capital invested in unsold merchandise.

- Liquidation Sales: For larger quantities of slow-moving inventory, consider hosting a liquidation sale to clear out the stock at significantly discounted prices. While the profit margin might be lower, it’s often better than holding onto inventory with diminishing value.

- Donations: Depending on the nature of your slow-moving items, donating them to charities or organizations could be a viable option. This not only clears out your storage space but also allows you to potentially claim a tax deduction.

Making Informed Decisions: Consider the Bigger Picture

While it’s important to address existing slow-moving inventory, a proactive approach is crucial for long-term success. Here are some additional considerations:

- Supplier Relationships: Building strong relationships with your suppliers can be beneficial. Discuss potential return policies or exchange options for products that might not sell as anticipated.

- Demand Forecasting: Utilize sales data and industry trends to forecast future demand for products. This helps with more accurate ordering and reduces the risk of overstocking and creating slow-moving inventory in the first place.

- Diversifying Product Mix: Regularly evaluate your product mix and consider diversifying your offerings. This can help cater to a wider range of customer needs and potentially reduce the risk of relying heavily on specific items that might become slow movers.

- Lead Time Management: Negotiate longer lead times with suppliers for products with slower sales velocity. This allows you to order smaller quantities initially and avoid overstocking.

Conclusion

Identifying and effectively managing slow-moving inventory is an ongoing process for any retail business. By using the critical measurements and strategies talked about above, you can acquire significant experiences in your stock performance. Finding a way proactive ways to address slow-moving items through targeted promotions, investigating alternative solutions, and carrying out techniques to prevent future issues can fundamentally help your business. Keep in mind, a well-managed inventory means expanded income, further developed extra storage usage, and at last, a healthier bottom line. By proactively dealing with your stock and staying ahead in front of likely slow-movers, you can guarantee your retail business flourishes and has the assets it needs to proceed with development and achievement.